3 Great Logistics & Supply Chain Online Learning Video Series

https://morailogistics.com/3-great-logistics-supply-chain-online-learning-video-series/

Hello everyone! We hope you’re enjoying your summer so far. This week we’d like to focus on increasing awareness about the logistics industry as a whole. There is a growing number of people outside of the logistics and supply chain industry who are now trying to become more aware of where their products are coming from and the entire process behind getting it delivered to your doorstep. So we scrounged the web to find you not just one online video series on logistics, but three!

1 – Introduction to Supply Chain Management

Arizona State University’s (ASU) W.P. Carey School of Business has released an open online video series on supply chain management in an effort to “inspire a new generation of supply chain management professionals across the country and around the world.”

2 – Supply Chain Brain’s Video Series

The folks over at Supply Chain Brain and Kinaxis have teamed up to create an online video series during their annual Kinexions Conference. They completed a set of video interviews with customers, analysts, and executives. While the videos mainly focus on attendees and people over at Kinaxis, they offer great insight from thought leaders in the industry and give a great overview on some specific topics in the logistics and supply chain industry.

3 – The Supply Chain Academy

The Supply Chain Academy is a special case for this list because it’s more than just a video series, they offer a series of massive open online courses (MOOCs) that grant you certificates by Dr. Simon Croon. He started this with colleagues at Warwick University in the hopes of providing a dynamic, engaging, and focused course series about the supply chain. The current course schedule is for sustainability and the global supply chain, but registration is now closed. Here’s the introductory video though:

Registration will open in July for the Fall 2013 class titled “The Management of Supply Chain Costs.” So if you’re serious about learning about the logistics and supply chain industry, we highly recommend registering and taking advantage of this free online course (you do get a certificate upon passing!).

We hope these videos provide you with a better grasp into the complex world of logistics and supply chain; getting products from point A to point B can be a very complex process! If you want to know what we do as a third party logistics provider (3PL) check out our core services. If you haven’t already check us out on Twitter (@MoraiLogistics), give us a follow or a @mention, we’re looking forward to engaging with you. Otherwise, stay tuned for next week’s post on our monthly Logistics Glossary Week series!

Industry Focus Week for July 2013: The Oil Industry

https://morailogistics.com/industry-focus-week-for-july-2013-the-oil-industry/

Last month we took a look at the retail industry and how its supply chain is affected with regards to recent news. We’re continuing the series this month by exploring the crude oil industry. If you have been keeping up with recent news, last Saturday the town of Lac-Mégantic experienced an unexpected tragedy when 73 black rail tankers carrying pressurized containers of crude oil was derailed.

The train was parked for an overnight shift change, the tankers decoupled from their locomotives for an unknown reason (as of yet) and rolled downhill without any drivers into the town centre, derailing and setting off a series of explosions. The explosions caused fires that lasted for hours; about 30 building were destroyed and a death toll of at least 15 with dozens unaccounted for.

This tragedy has given light to concerns of the logistics behind crude oil transport and below we will take a look at how development in the crude oil supply chain has changed with regards to the modes of transportation and the factors that affect crude oil costs.

Crude Oil Transport Shifting to Rail

The revival of oil trains in North America stemmed from the Bakken shale in North Dakota due to fracking (i.e. hydraulic fracturing) creating a huge amount of product that needed to be moved without too many options with regards to the pipeline. This led to the oil industry turning to rail to move crude oil to refineries at the East and West Coasts as well as the Gulf Coast. This growth led to huge shipments of oil. For example, in Canada’s railroads alone rail transport for crude oil has gone from 500 carloads in 2009 to a predicted 130 000 to 140 000 this year, according to the Railway Association of Canada.

Apart from being a highly efficient mode of transport for crude oil, costs for train transport can also be lower due to the crude oil in trains being made entirely of tanker cars of oil. This effectively creates an above-ground pipeline and is more cost-effective than traditional the traditional mixed cars of boxcars, flatbeds, etc. (a.k.a. ‘manifest trains’).

Supply Chain Factors that Affect the End Cost of Oil

We’d like to finish this off with a look at two main factors, with regards to the logistics and supply chain aspects of oil transport, lead to changes in cost for the end user.

Mode of Transportation – As discussed above, consumer end cost rises if we limit train movement. If you change the cost from intermodal/rail to truck transport, costs will increase. Equipment shortages can also affect the prices of oil as in order to supply the demand, companies will have to seek alternative modes of transportation in order to meet consumer needs. Disasters along the supply chain can have a devastating impact on the price of oil, something we have already been made aware of in 2010 when the BP oil spill on the Deepwater Horizon rig happened.

Supply & Demand – Obviously one of the biggest factors that affect the end cost of oil is how much we have available to distribute and how much we need. There are also global oil inventories that affect pricing. Global oil inventories exist to balance the supply and demand. When production exceeds the demand for oil, the excess oil is stored. This way, when consumption exceeds the current supply of oil, the oil inventories can be tapped to meet the demand but could end up increasing cost for the end user.

We hope you enjoyed this month’s industry focus on the oil industry. If you liked this blog post and you want to read more of our content, don’t hesitate to subscribe to our blog. Or if you want more logistics and supply chain content throughout the day, follow us on Twitter! If you’re interested in what we do as a 3rd party logistics provider, feel free to check out our core services. Otherwise, we’ll catch you next week!

4 Interesting Logistics and Supply Chain Infographics

https://morailogistics.com/4-interesting-logistics-and-supply-chain-infographics/

Hi everyone! Hope everyone had a great Canada day last weekend or if you’re in the United States, a great 4th of July! For this week we’d like to share with you a couple of cool logistics infographics that we’ve stumbled upon in the last little while that we thought were worth sharing.

1 – The Cost of Shipping

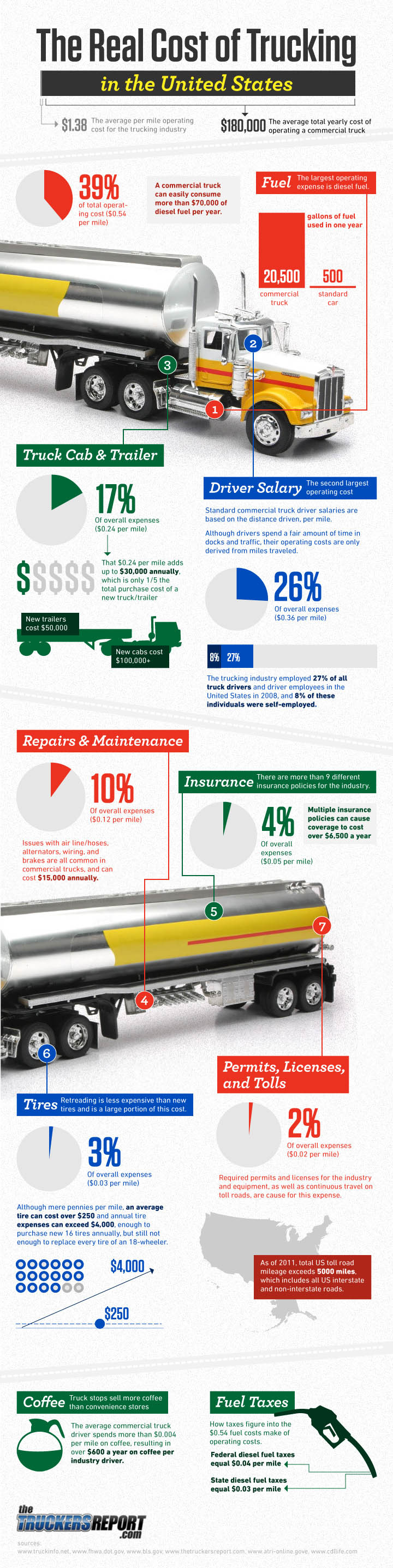

2 – The Real Cost of Trucking in the US

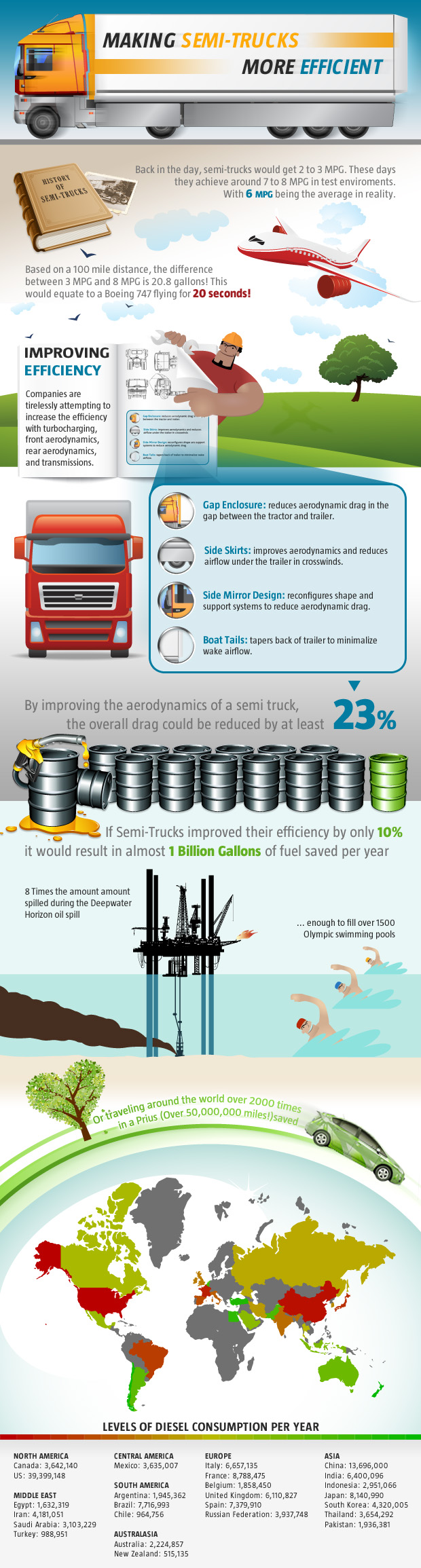

3 – Making Semi-Trucks More Efficient

4 – How Safe is US Rail?

We hope you found these infographics interesting, useful, and entertaining! Stay tuned next week for more updates on logistics and supply chain content! Feel free to check us out on Twitter (@MoraiLogistics) or check out our core services to see what we do as a third party logistics provider. Catch you next week!

Logistics Glossary Week for June 2013

https://morailogistics.com/logistics-glossary-week-for-june-2013/

Hi everyone, we hope you’re enjoying your summer so far! As mentioned in our previous post, we’re going to be continuing our end of the month Logistics Glossary Week, where we will be covering logistics terminology that you may or may not be familiar with that has to do with news that’s currently happening today. So let’s get started!

Third Party Logistics Provider

Definition: A 3rd party logistics or 3PL provider is a firm that provides multiple logistics services for use by customers. Usually these services are bundled to offer an integrated service solution. Common services are transportation, warehousing, cross-docking, inventory management, packaging, and freight forwarding. They can take manage any or all parts of the supply chain process and sometimes they can specialize in particular types of transport (for example alcohol, chemical, or refrigerated goods).

We’ve decided to kick off out Logistics Glossary Week with a definition of what a third party logistics provider actually does because the recent findings from the 24th annual ‘State of Logistics’ report by Penske Logistics. The results suggested that while the logistics industry should be prepared for a ‘new normal’ of slow growth, companies have started to become more reliant on 3PL services due to its potential to cut costs, as well as to have access to a body of supply chain experts who are comfortable and connected within the industry.

Freight Carrier

Definition: Freight carriers are companies that specialize in providing transportation of goods (i.e. freight) from one place to another, they can sometimes be referred to as ‘for hire’ carriers. Usually these companies own their own equipment and can have any or all of the following transportation services: trucking, rail, airlines, and ships.

This term is also relevant to the ‘State of Logistics’ report. While freight carriers offer different modes of transportation, we’d like to bring the focus on trucking. As you may have heard, the logistics industry is currently having a staffing problem with regards to trucking. Truck drivers were shown to have a fewest potential workers trained to fill the growing demand for them (trucking services rose 2.9%). As stated by the report, about 17% of the current driver population is under the age of 35, while a large proportion of truck drivers are on their way to retirement.

Cross-Border vs. Domestic Shipping

Definition: If you are shipping domestic, it means that your shipment is happening within the same country from origin to destination. Cross-border is the opposite, where packages at origin will have a final destination in a different country from origin.

We want to bring light to this definition because we recently ran into an interesting blog post that talked about a report issued by the World Economic Forum and the Boston Consulting Group on innovations that will change the supply chain. One of the things that are in development is a ‘smart’ visa system for automated check-in, security, and border control. This can potentially reduce the time it takes to cross borders by eliminating long lines at airport screening points and land border crossings while enhancing security. Biometric identity checks can also add to the speeding up of the processing. Furthermore, it has the potential to cut costs due to the fact that the visa applications could be standardized across multiple countries that would provide all relevant data to officials in all participating nations.

We hope you’ve enjoyed our second Logistics Glossary week post and that you have a wonderful long weekend (Happy Canada Day!). To keep up with our posts, and to see other content related to logistics and supply chain don’t hesitate to follow us on Twitter or subscribe to our blog! If you’re interested in what we do as a company, feel free to check out our services. Looking forward to seeing you in July!

3 Strategies for the Logistics Industry to Prepare for the Coming Years

https://morailogistics.com/3-strategies-for-the-logistics-industry-to-prepare-for-the-coming-years/

The findings of the 24th annual ‘State of Logistics’ report by Penske Logistics was released by the Council of Supply Chain Management Professionals (CSCMP) this week during their Annual Global Conference. While we’ve been a majority of articles suggesting that the outlook for the future of the logistics and supply chain industry is ‘slow growth.’ This is based on reports from the previous years’ showing relatively slow growth since the recession of 2007-2009.

This week, we’ve decided to focus on a more positive outlook from the results of the report by looking at a couple of strategies for companies to manage their companies to a more successful outcome in the coming years.

1 – Continue Planning to do More with Less

Rosalyn Wilson, the author of the ‘State of Logistics’ report states in her presentation this past Tuesday that since the great depression that the strategy has been to “do more with less.” In a continuation of previous years’ results, it seems that the ‘new normal’ in the logistics and supply chain GDP growth rate is between 2.5-4%.

She warns that these are due to higher unemployment levels and slower job creation and consumers are also more risk-averse. But this is not necessarily the case for all companies. The rise in e-commerce has changed the way inventory is distributed and managed. Also, new technologies are underway that can severely cut costs with regards to supply chain aspects like tracking and tracing (e.g. see RFID).

It seems that the solution is to keep companies light and to keep risk low for bigger companies. This is reflected in some good news for those in the 3rd party logistics sector. The report showed that third-party logistics has risen in revenues by 5.9% in 2012 as companies start to realize the value of outsourcing their logistics.

2 – Maintain Sustainability Strategies

In the realm of cost-cutting strategies, there is a great deal of promise in continuing to explore sustainability strategies in order to keep costs low throughout the supply chain. As discussed in a previous blog post, sustainability strategies have the primary motivation of being better for the environment. Strategies like relying on solar and wind power, as well as other green warehouse strategies (e.g. ‘smarter’ warehouses that control lighting and temperature, etc.) as a move to create a ‘net-zero’ warehouse have the added benefit of cutting costs in the long-term.

If this report is right to suggest that the logistics industry growth is going to be a sluggish one, this works out to be a great investment strategy for the long term as companies prepare have needed to rely on creating new sites. This was to accommodate for the fully absorbed warehousing capacity of 2012, which created a 7.6% increase in warehousing costs. Building better warehouses from the start seems to be the direction to head in for new construction projects.

3 – Focus on Education and Staff Retention

There is also a worrying report that there are several holes that will need to be filled in the ensuing years for the logistics industry. The results from the report show a growing need for companies to rely on part-time workers as opposed to adding new full-time staff. But as a long-term strategy, this might not be the smartest plan. Staff retention is something that the industry needs at this moment as a growing proportion of staff are looking to be on their way to retirement.

Furthermore, there is a need for people to fill certain positions along the supply chain that have been well-known for a while. For example, truck drivers have been shown to have the fewest potential workers trained to fill them. The results from the report have continued to reflect this, showing that 17% of the current driver population is less than 35 years of age while the staggering majority is on their way to retirement.

Companies are going to need to introduce the idea of logistics to the masses earlier on, there is still a lack of awareness of the logistics industry as a whole and it seems that in order to fill these positions, education is the way to go. There is some promise though, as new trends in higher education have seen the gap in lack of programs dedicated to the logistics and supply chain industry and have already piloted degree programs out in both the undergraduate and masters level. There are also initiatives to reach the high-school population as well!

A slow growth is not necessarily bad news, growth is still growth. US logistics costs rose to $1.33 trillion which is a 3.4% increase from last year. People will always need logistics services as global demand in getting products where they need to be continues to rise. The outlook for these companies should be a positive one and the spirit should be to rise to the challenges, hopefully to come out on top!

If you liked this blog post, why not subscribe to our blog? If you’re interested in what we do as a 3rd party logistics provider, don’t hesitate to check out our services. We’re also in the twittersphere, so give us a follow to get the latest logistics and supply chain news! We’ll catch you next week!

Industry Focus Week for June 2013: The Retail Industry

https://morailogistics.com/industry-focus-week-for-june-2013-the-retail-industry/

With recent news talking about the current controversy surrounding the Rana Plaza tragedy in Bangladesh, this week we’d like to focus on the retail industry as a whole and explore what is currently happening and how supply chain and logistics ties into all of the news trends. So we’ve been motivated to write a monthly post on the trends.

A Challenge for Physical Stores to Remain Relevant

Ever since the development of the Internet the concept of online retail, or e-stores, have been present and has been developing at a relatively rapid rate. Physical stores work to compete with online retail sites but also have to work with integrating online retail as a part of their services as well.

Physical stores have the advantage of giving consumers the opportunity browse, try on or try out, and purchase items on the spot (all without the added cost of shipping!). This doesn’t seem to be enough as certain sectors in the retail industry suffer big blows from the major online retailers. Case in point: Amazon and the book store crash that happened a couple of years ago. That’s not to say the physical stores in some sectors have merged beautifully with e-commerce, apparel retail being one of them.

So how does online retail tie in to the supply chain process? Well, to start it has been a great influencer in the growth companies, which in turn has led to analysis in a company’s manufacturing and supply chain strategies. We’re going to focus on clothing and apparel in our case study below to see how other factors have affected how manufacturing and supply chain is changing:

Case Study: Apparel Retail

In the world of logistics, there is an incredible amount of complexity that goes into getting your product from a factory to store shelves or your doorstep. The above-mentioned tragedy in Bangladesh has stimulate the European Union to press for Bangladeshi authorities to immediately initiate international labour standards. Furthermore, agreements with the International Labour Organization (ILO) have proposed short-term and medium-term steps to improve labour conditions.

These current attempts stem from consumers now wanting companies to be more transparent with regards to their supply chain. While the move to create better conditions for offshore workers are underway, companies in apparel retail are creating ways to take advantage of this as a marketing strategy. One great example is Planet Money, which is an online retail store that sells shirts that tells the story of its creation. It takes you on the journey from being made in Bangladesh to being brought to your doorstep.

We hope you enjoyed this quick glance at the retail industry. Stay tuned for next month when we feature another industry and give you a quick breakdown of another interesting industry sector for the logistics and supply chain industry. If you’re interested in the role we play in logistics, feel free to check out our services. Also, we’re social on Twitter so don’t hesitate to give us a shout and let us know how we’re doing!

Logistics Glossary Week for May 2013

https://morailogistics.com/logistics-glossary-week-for-may-2013/

Hello everyone! We’re going to start a series where we end each month with a glossary of some logistics key words for those of you that are outside of the logistics world. We’re kicking new monthly blog post off with some basic terminology that is currently important to know with regards to logistics and supply chain news this week:

Offshoring

Definition: the process by which one uses an outsourcing service provider located in a country other than where the client is located.

This is currently a hot topic today especially considering the controversy surrounding the Rana Plaza tragedy in Bangladesh. While sweat shops have always been an issue when it comes to offshore manufacturing, consumers are now becoming more and more demanding of supply chain awareness. Western suppliers are currently faced with the challenge to keep their supply chain less sweat-shop and more fair-trade.

Nearshoring

Definition: A term coined as sort of the opposite of offshoring, where companies look to find an outsourced service provider located closer to the country of origin or within the country itself; usually in a move to solve current supply chain issues such as cost-cutting.

Nearshoring is currently a hot topic as big companies are thinking about (and some are already) making a move to bring their manufacturing closer to home. With the current difference in pricing lowering in North America (the US and Mexico specifically), the pricing power of Chinese offshoring is constantly diminishing. Meanwhile, American companies are looking to Mexico to solve their supply chain needs.

Tracing and Tracking

Definition: These two go hand-in-hand. It is used in the logistics industry to refer to the process by which shipment movements from origin to destination are recorded and monitored.

This term is relevant to current trends because as we mentioned in one of our previous blog posts, creating a more synchronized and efficient way to do tracking and tracing is extremely beneficial to the logistics industry. Not only can an improved system reduce errors along the supply chain, it can also make it harder for criminal activity along the supply chain (both cyber and real-world) as well as reduce costs! The current development for tracking and tracing to look out for is Radio-Frequency Identification or (RFID).

SOP: Standard Operating Procedures

Definition: a collection of documents, or manuals, that outlines how and organization carries out their activities and procedures. In the world of logistics, this is the guideline for how the operations in the supply chain should be executed.

This is currently a hot topic as the demand for cost-cutting in many product-based industries are looking to their logistics and supply chain to find solutions. For example, the recent recession has caused a conundrum in the restaurant industry as consumers demand higher quality food at lower prices. And now Standard Operating Procedure visibility is now something that supply chain executives in the restaurant industry are attempting in order to meet the demands of consumers so that the end product results in better quality food at the same (or lower prices).

And this wraps up our first month of blogging at Morai Logistics! We really hope you’ve been enjoying our posts so far and we hope you have a stellar weekend. To keep up with our posts, and to see other content related to logistics and supply chain don’t hesitate to follow us on Twitter or subscribe to our blog! If you’re interested in what we do as a company, feel free to check out our services. Looking forward to seeing you in June!

3 Sustainable Supply Chain Initiatives that Rock!

https://morailogistics.com/3-sustainable-supply-chain-initiatives-that-rock/

As mentioned in our last blog post, the logistics industry is currently trending with green and sustainability initiatives. Research from PwC has already shown that 42% of supply chain executives rank sustainability as highly important to their companies, and 67% agreed that supply chain sustainability will be even more important in the future. Apart from the notion that these projects not only attempt to reduce the potential damage to our ecosystem (via carbon footprint reductions, etc.) and promote the notion of fair trade, there are more interesting factors that also stimulate this move.

One of them is that there are indeed hints at cost-savings in the supply chain for the future. We mentioned before that companies are not only talking about nearshoring, but have already attempted to bring their supply chain ‘back home.’ This is due to the fact that recent trends have shown that China is losing its pricing power as the US and especially Mexico move to match China by 2015. Though this trend may require some watch as some industrial real estate investors have recently made a move to target logistics property in China. Another major factor is the increase of awareness campaigns in the logistics industry. Research by Smith & Associates shows that mobile technologies and social media are becoming important influencers in the supply chain world, suggesting that this is a contributing factor behind the current trend.

This week we’re going to highlight some of the sustainability initiatives that we thought to be interesting and worthy of mention, starting with a cool cloud-based project:

Enterprise Sustainability Platforms

Backed by three PhD environmental scientists and policy analysts, the EcoShift development team has created a cloud-based solution to help companies find out more about their suppliers’ sustainability information. How it works is that buyers can analyze supplier sustainability information and risk while suppliers have access to a dashboard to see where their sustainability efforts rank compared to industry peers. This information allows buyers to see who the sustainable suppliers are. Suppliers, on the other hand, get access to information on how to improve their own efforts.

Green Warehouse Projects

Warehouses consume quite a bit of energy. Apart from being a cost-saving initiative, they also lessen the harm that high energy consumption does to the environment while gaining respect from customers and the community.A great post by Maida Napolitano over at Supply Chain 24/7 offers a great summary highlighting some great attempts. Warehouse power initiatives are now attempting to have ‘net-zero’ buildings; a move to generate as much energy as it uses up over a year. This leads to companies in the industry investing in solar- and wind-powered technology for their warehouses. Another noteworthy attempt to reduce power usage is by having a ‘smarter’ warehouse. These typically consist of an energy management system that uses submetering to monitor equipment energy use and performance. These efforts, combined with energy saving fans, lights, etc. showcase a real attempt at a green warehouse.

Logistics and Supply Chain Awareness Campaigns

As mentioned above, mobile technology and social media are becoming more and more important to the world of logistics and supply chain. Efforts to show awareness through campaigns such as the UPS ‘We Love Logistics’ campaign shows not only that awareness can lead to better business, but also that people are indeed actually interested in finding out more about the logistics industry as a whole. One recent noteworthy campaign is Starbucks’ Behind the Scenes campaign. With a supply chain that spans more than 19 countries, they definitely do a good job showing how interesting it is to start from where they get their cocoa beans to serving you that steaming cup of coffee.

While there are other efforts that could be made of note, these three examples are offer a great insight into how the logistics and supply chain industry are trying to provide a clean, green business. It is nice to see that these attempts are trending because it shows that companies are becoming more and more concerned about the environmental factors of their supply chain process.

3 Trends on the Future of Logistics to Keep an Eye On

https://morailogistics.com/3-trends-on-the-future-of-logistics-to-keep-an-eye-on/

We’ve reached an era today where people are becoming more and more aware of how companies move their goods and where they are manufactured. There is even a Kickstarter company that gives you the breakdown of where your shirts are coming from! We are also starting to get more and more aware of how supply chain services are affecting our environment by increasing efforts to create a more sustainable supply chain. This includes taking advantage of new technologies in order to accommodate today’s large transportation and supply chain demands. New advancements in e-commerce and the changing trends in global logistics has been a player in these shifts.

We’ve narrowed our list down to three main trends to watch for, and these trends will definitely affect the end user hopefully by being able to create a more efficient and cost-effective supply chain in the near future.

1 – Synchronizing Tracking on the Supply Chain

There is a lot of buzz in the logistics community these days on Radio-Frequency Identification (RFID) technology. Companies are starting to look into synchronizing how packages are tracked especially when it comes to services that involve global logistics or supply chains that involve multiple modes (i.e. intermodal services).

So what does this mean for both manufacturers and customers? The main benefits of RFID implementation in the supply chain are laid out quite nicely via a case study post on RFID for international supply chain management. Essentially, RFID tags can be read from a distance (with no line of site needed) and are easily tracked. This allows for a more visible supply chain that increases tracing on internal shrinkage, thereby reducing it, as well as makes it easier to detect counterfeit products (all authentic products can be given a unique ID).

For the manufacturers and distributors, the ease of tracing and tagging reduces the number of mistakes along the supply chain and the scanning process can also reduce the time it takes for shipments to move. On the customer end, there is less hassle when it comes to tracking and receiving products. While this may sound like a win-win, RFID technology is still not a perfect solution due to two main issues: reader collision and tag collision. The scanners can get easily confused when two tags overlap, so there has to be a system in place that allows for scanning tags one at a time.

2 – Creating a Sustainable Supply Chain

There is a new trend for consumers to want to be more aware of the process by which goods arrive at their door. This arose out of consumers wanting to be able to make informed decisions when purchasing with regards to both sustainability and fair trade issues, and a growing prevalence in ‘bringing products back home’ (i.e. keeping things local). So it is not surprising that companies have started to think about and even implement some changes in order to have a greener, sustainable supply chain. Concurrently, government run initiatives are being put in place to help set in motion its development such as the Clean Energy Manufacturing Initiative (CEMI).

Companies are now taking advantage of said initiatives by having wind and solar powered manufacturing plants, which in turn have been shown to not only reduce their carbon footprint but also, in some cases, cut costs for end consumer prices. This creates a win both for the environment and the consumer.

Apart from environmental concerns, part of the sustainability trend also involves fair-trade. This issue, while mostly prevalent in the food industry, is becoming critically important in consumer buying decisions. The desire to buy ethically clean products is extending to more and more products to the everyday consumer. As mentioned earlier, the Kickstarter project is one that attempts to fully focus on this for their brand imaging, but major retailers are starting to participate as well even in the luxury sector.

There are plenty of benefits on the logistics end apart from satisfying consumer buying trends that further stimulate the initiative to go for greener and more sustainable supply chain practices. It can protect market share and reduce risk premiums as well as cut costs for both manufacturers and consumers while increasing supply chain efficiency. Thus it seems like in the future we will start to see more and more companies striving for producing sustainable products at every stage of the process and promoting their initiatives to create transparent ethical business conduct and sustainable products.

3 – Nearshoring and Bringing Manufacturing Back Home

Finally, with our current globalization trends we are noticing that more and more companies have started thinking about bringing their manufacturing closer to home. Nearshoring is the transferring of business processes to nearby country, often bordering your own. It is a trend that has taken precedence in companies due to the fact that certain costs have been increasing in typically low-cost countries like China.

Recent research has shown that more and more manufacturing executives would like have the US or Mexico as their preferred location for nearshoring. This is due to the fact that these nearshoring initiatives led to a 5-10% reduction in ‘landing costs’ already. The trends suggest that by 2015, US manufacturing costs will match that of China while manufacturing in Mexico and India stay strong. These trends suggest a move out of Asia with a focus on the US and Mexico as new manufacturing hubs.

At the end of the day, there are many developments that have not been discussed as current trends for the future of logistics (but be sure to stay tuned for future posts!). But these three issues are currently trending and should be watched carefully. It will be interesting to see how these factors will tie in to manufacturers, third party logistics providers, and all other parties along the entire supply chain up to the end consumer.

If you have any questions, please feel free to give us a shout. Otherwise, feel free to see where we fit in the supply chain as a 3rd party logistics provider by checking out what we do. Otherwise, have a great rest of the week and enjoy the long weekend!

3 Things Promoting Lowest Total Cost Can Say About 3PL Providers

https://morailogistics.com/3-things-promoting-lowest-total-cost-can-say-about-3pl-providers/

Whether you’re shopping around for a third party logistics (3PL) provider to take care of your transportation needs or just interested in how cost is determined for your shipments, this month we want to bring awareness to one crucial aspect: lowest rate vs. lowest total cost.

In order to describe the difference between lowest rate and lowest total cost, let’s use the example of a request for a shipment from Portland to Boston. Often transportation companies will look for the lowest available rate and quote that in order to close a deal and guarantee the business. While this sounds enticing, prospective shippers should be careful. The only information the lowest rate can get you is the cost of the shipment to transport from one place to another.

On the other hand, estimating the total cost provides a clearer picture because it includes additional considerations such as: drop and pull at origin/destination, size of equipment, mode option (intermodal or truck), lowest cost per pound, etc. That being said, what you might actually find is that the total price you pay might actually be lower with a higher initial rate estimate because it has less additional costs.

Our company believes in getting you the lowest total cost, and we believe that when it comes to 3PL providers getting a total cost analysis tells you three things:

1 – The Company is Client-Focused

Anybody can get a quote for a rate. A great 3rd party logistics provider that offers to quote you via lowest total cost has to listen to you carefully to know your needs. This involves much more commitment from representatives of the company who interact with you. They are taking that extra step to put your needs first. Understanding your business is key!

2 – The Company is Resourceful

A company who gives you rates with lowest total cost shows that they are resourceful. They took the time to analyze your company’s needs and explored all cost options, charges, and modes of transportation available for your shipments. This additional information requires being connected to the right people and resources in the world of logistics.

3 – The Company Has a Wealth of Knowledge in the Industry

Companies that only offer the lowest rates can suggest a lack of research into the entire supply chain process. Often these ‘rates’ get a transportation company in the door yet does not allow their rate to actually pick up your freight. This means that the providers may have quoted far too low in order to grab the attention of its shipper. But going with the lowest rate can sometimes be underestimated and you can get slapped with various additional costs.

So make sure you ask the right questions when choosing a third party logistics provider and take into account the difference between the lowest rate and the lowest total cost! If you have any questions at all feel free to contact us, our highly experienced Client Success Specialists can tell you anything you need to know about getting you the lowest total cost!